简介:EXPEC 高级研究中心和

哈里伯顿公司联合研发出一套新型的激光

射孔技术,引起业内关注。

沙特阿美公司第一个试用该项技术进行“现场激光”射孔作业,与传统射孔工艺相比,地层伤害确实大为降低。激光射孔法能消除传统方法造成的地层压缩伤害,保证孔壁无压缩变形,大大增强产液的效率。

The EXPEC Advanced Research Center (EXPEC ARC) and Halliburton have joined forces to develop a novel perforation method using laser technology, and the industry is taking notice. Saudi Aramco is the first production company to test the “in-situ lasing” method, which promises much less formation damage compared to conventional perforation techniques.

In completing a gas or oil well, perforating a well is an essential step for production of hydrocarbon fluids from the reservoir rock into the wellbore and onward to the surface. Perforations are holes made through the steel casing wall and cement into the rock formation which permit hydrocarbon to flow into the well. Current industry techniques employ explosive charges to create the perforations, causing compaction in the rock and reducing the ability of the hydrocarbons to easily flow into the well.

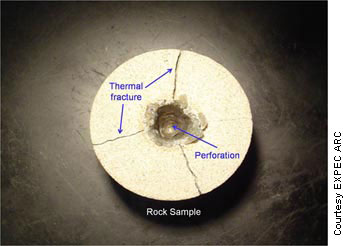

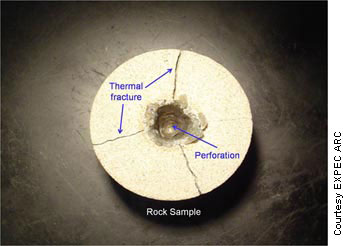

A laboratory core sample shows the fractures resulting from the in-situ lasing perforation process.

The in-situ lasing method avoids such damage to the rock formation in that no compaction is created. A high-energy laser beam is aimed into the formation, which vaporizes the rock and creates a perforation with a permeable wall surface, EXPEC ARC states.

Laboratory results have demonstrated that laser perforation generates thermal stresses that fracture a well’s surrounding rock, thus increasing permeability around the perforations and facilitating easier inflow of hydrocarbons. EXPEC ARC states that an immediate application of laser perforation includes facilitating hydraulic fracturing in openhole horizontal wells (oriented fracturing), which can greatly enhance the wells’ production capability.

“The implementation of this innovative technology will open the door for significant applications in our oil and gas industry, furthering our major goals of reducing costs and increasing production,” said Mohammed Y. Al-Qahtani, executive director of Petroleum Engineering and Development for Saudi Aramco.

“This successful laboratory laser perforation of casing and rock samples has brought us closer to deploying laser energy in situ for well perforation and fracture initiation,” said Nabeel S. Habib, Saudi Aramco’s Production Technology Team chief technologist. “This in-situ laser perforation will also set the groundwork for further research and applications in petroleum engineering, including laser drilling.”

杨宝剑 是全球

石油网的高级技术编辑,在

石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对“新技术新产品”的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:

allenyo@zhenweiexpo.com 欢迎您提供手中的最新技术文章!